- MOTOR WINDING RESISTANCE TEST PRO

- MOTOR WINDING RESISTANCE TEST SOFTWARE

- MOTOR WINDING RESISTANCE TEST PLUS

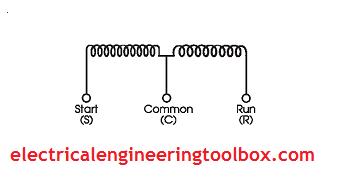

A 3-phase connection is preferable in the winding resistance test, even if the testing is performed phase by phase, because it reduces testing time as the user has to go on the top of the transformer less times. The winding resistance test is done with four wires method, by injecting DC current through the winding and measuring the voltage drop. The winding resistance test is performed with specific transformer ohm-meters which, unlike the typical micro-ohmmeters for contact resistance measurements, have higher compliance voltage to deliver the energy needed to saturate the windings and stabilize quicker the reading, to provide an accurate and repeatable measurement. Also, those components within a winding circuit, such as bushing connections and load-tap changer switches, are included in this testing. What makes a winding resistance test set different than a traditional low resistance ohmmeter, is that they are able to overcome the effects of large inductances which are associated with transformer windings. Required characteristics for winding resistance test sets The winding resistance tests are also part of periodic maintenance programs for finding problems that may reduce the system performance and can lead to unexpected power failures. Winding resistance tests are also typical on new transformers after delivery to site to detect any damage during the transport, and as initial transformer reference for comparison with future measurements. On site, the winding resistance test is performed to evaluate possible winding problems or damages, such as short turns, open windings, internal connection problems, hot points and the condition of the tap changer. In the factory, the winding resistance test assure proper manufacturing according to design, serves also to calculate conductor losses and as variable magnitude during thermal test related to winding temperature. The winding resistance test is used both in factory tests and for field operating verification. Related testers must cope with the strong inductive load to apply the necessary DC current to magnetize the winding and stabilize the current, besides taking into account the connection group and the temperature. The winding resistance test of transformers, tap changers or motors involves a particular challenge in resistance testing, due to the highly magnetic nature of the windings. Resistance testing of electrical equipment covers a wide range of techniques depending on the nature of the element tested and the target of the test. Solutions for Winding Resistance Test – SMC

MOTOR WINDING RESISTANCE TEST SOFTWARE

Smart Test Tools relay testing software.GOOSEMeter One IEC 61850 message monitor.SMC-12 MCB circuit breaker testing system.EDA-III motor insulation resistance test.Transformers, motors and generators test equipment.PTE-30-CH electrical substation maintenance chronometer.PME-20-PH electrical substation maintenance phase angle meter.Circuit break timer test set PME-500-TR.

MOTOR WINDING RESISTANCE TEST PRO

MOTOR WINDING RESISTANCE TEST PLUS

PTE-100-C Plus secondary injection test set.PTE-100-C Pro secondary injection test set.Mentor-12 universal relay testing system.TriRaptor Three-phase High Current Injection.Solutions for Electrical Contractor Services.Power Transformer Maintenance Solutions.Solutions for Electrical Substation Maintenance.

0 kommentar(er)

0 kommentar(er)